Last week a massive explosion in Beirut at a storage facility housing 2,750 tons of ammonium nitrate killed at least 137 people, displaced 300,000 residents, and spread debris and damage for a two-mile radius.[1] While some government officials, reporters, and international observers suspected terrorism, Beirut authorities concluded that negligence and mismanagement of the facility were the principal causes. While accurate, this conclusion misses a great deal of historic context.

The Beirut explosion is the latest in a long line of ammonium nitrate blasts. For people residing in the United States, the most well-known incident involving ammonium nitrate occurred in 1995 when domestic terrorists Timothy McVeigh and Terry Nichols used the substance as the catalyst to kill 168 people inside the Alfred P. Murrah Federal Building in Oklahoma City. But, this was by no means the largest ammonium nitrate explosion in U.S. History. Few Americans will recall an accidental explosion of the substance in Texas in 1947 that killed nearly 600 people. Smaller explosions have also occurred in Kansas City and Waco. Internationally, ammonium nitrate explosions in Germany, France, North Korea, Belgium, China, and Mexico have killed scores of people.

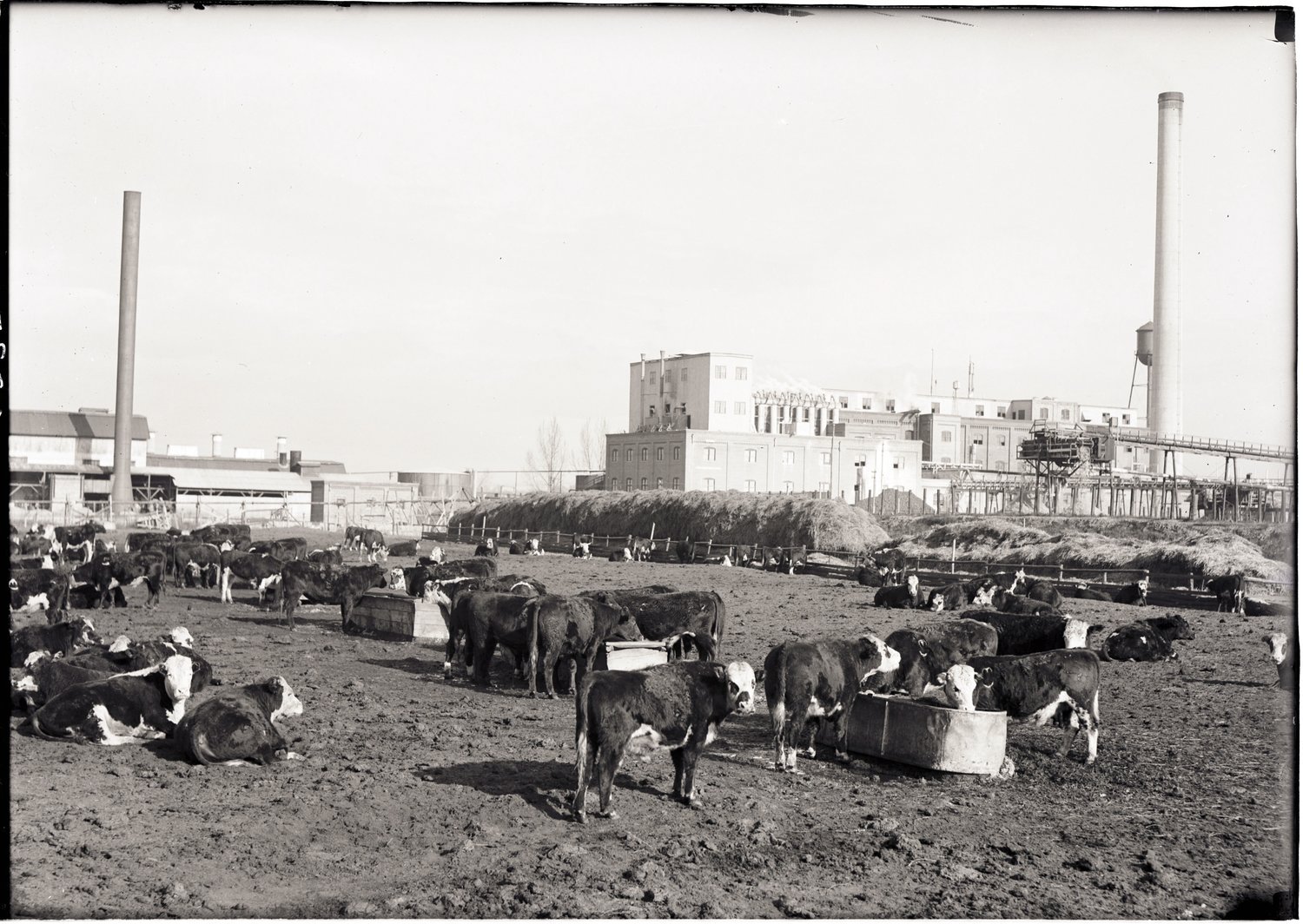

Though ammonium nitrate explosions grab headlines, they generally obscure why the compound occupies its place in the world today. Approximately 80% of all manufactured nitrogen in existence today is used in agriculture and is made by synthesizing ammonia (NH3). Ammonia – and derivatives such as ammonium nitrate - are cheap and supply nitrogen in a form plants can use. This is critical since nitrogen is the most essential element in plant growth (Phosphorous and Potassium are next in line). It constitutes 78% of Earth’s atmosphere and is present in every living cell. However, it has to be ‘fixed’ into a form that can be used by plants. Most livestock manures, once decomposed, supply usable nitrogen. Plants from the legume family such as alfalfa, peas, clovers, and beans possess Rhizobium bacteria that transform inert nitrogen into plant food. This is why, until the middle of the twentieth century, the majority of the world’s crop farmers also cared for livestock and rotated their crops. They needed a ready supply of nitrogen (and other nutrients).

German chemist Fritz Haber changed all of this in 1909 when he synthesized ammonia through what would eventually become known as the Haber-Bosch Process. Given the timing of the achievement and the fact that ammonia is highly volatile, the Haber Bosch process was used to greatest effect making explosives during World War I. Armed with the new process following the war, large chemical companies employed surpluses of ammonia to manufacture fertilizer. Since the process of synthesizing ammonia involved fossil fuels such as natural gas, petroleum companies joined the fray. Consequently, companies such as Shell and Monsanto were among early manufacturers.

After World War II, the quantity of ammonia exploded in developed nations such as the U.S. where farmers, seeking to dominate the world grain and soybean markets, applied ammonium nitrate and anhydrous (liquid) ammonia liberally to crops in the Midwest and Great Plains. With cheap and abundant fertilizer available in quantity, farmers no longer needed to devote lands to raising livestock, planting legumes, and rotating fields. In the developing world, ammonium nitrate enabled countries such as India to harvest unprecedented quantities of rice, corn, cotton in what has been called the Green Revolution. By the 1990s, nitrogen synthesized by the Haber-Bosch process accounted for 75% of the world’s total available nitrogen.

To say that manufactured ammonium nitrate is ubiquitous is an understatement. It feeds the American lawn addiction, as almost all of the nitrogen content in today’s lawn “weed and feed” products comes from ammonium nitrate. Corn provides a more precise metric for synthetic nitrogen usage. In 2019, farmers in the United States planted 91.7 million acres of corn, applying an average of 250 pounds of synthetic nitrogen per acre. This translates to a total usage of nearly 11.5 million tons on this one crop. At this rate, the quantity of ammonium nitrate that exploded last week in Beirut could have supplied one season’s nitrogen needs for 22,000 acres of corn.

All of that synthetic nitrogen is not innocuous, as the tragedy in Beirut shows us. Studies have shown that inorganic nitrogen sources such as ammonium nitrate are more likely to leach into the soil than nitrogen that is organically derived. These nitrates create hostile environments for organisms in the soil. When those nitrates run off, they pollute surface and groundwater and lead to various forms of pollution in lakes and streams. Since much of this drains into the Mississippi River, nitrates are principally responsible for a massive “dead zone” in Gulf of Mexico, where the river enters the ocean. Excess nitrates have also been linked to stomach cancer and infant disease such as Blue Baby Syndrome. Moreover, since synthesizing fertilizers such as ammonium nitrate requires heavy burning of fossil fuels, present and future conversations about climate change must address their contributing role.

As the smoke clears from the ammonium nitrate explosion in Beirut, our questions about this tragedy need to extend beyond why such huge quantities of this compound were being stored in hazardous conditions. The fact that our food systems are so entangled with a substance that is equally potent as a fertilizer and an explosive should give us pause. While it is unlikely that we will entirely wean ourselves from synthetic fertilizers such as ammonium nitrate, a more just relationship with fellow humans and fellow organisms requires that we re-consider our dependence on it.

[1] Figure as of August 8, 2020.

For Further Reading

Leigh, G.J. The World’s Greatest Fix: A History of Nitrogen and Agriculture. (New York: Oxford University Press, 2004).

Olmstead, Alan L. and Rhode, Paul W. Creating Abundance: Biological Innovation and American Agricultural Development. (New York: Cambridge University Press, 2008)

Russell, Edmund. War and Nature: Fighting Humans and Insects with Chemical from World War I to Silent Spring. (New York: Cambridge University Press, 2001).

Smil, Vaclav. Enriching the Earth: Fritz Haber, Carl Bosch, and the Transformation of World Food Production. (Cambridge, Mass.: MIT Press, 2001).